Business magnet: Russia has created a new type of reactors for the extraction of "green" energy

- Статьи

- Science and technology

- Business magnet: Russia has created a new type of reactors for the extraction of "green" energy

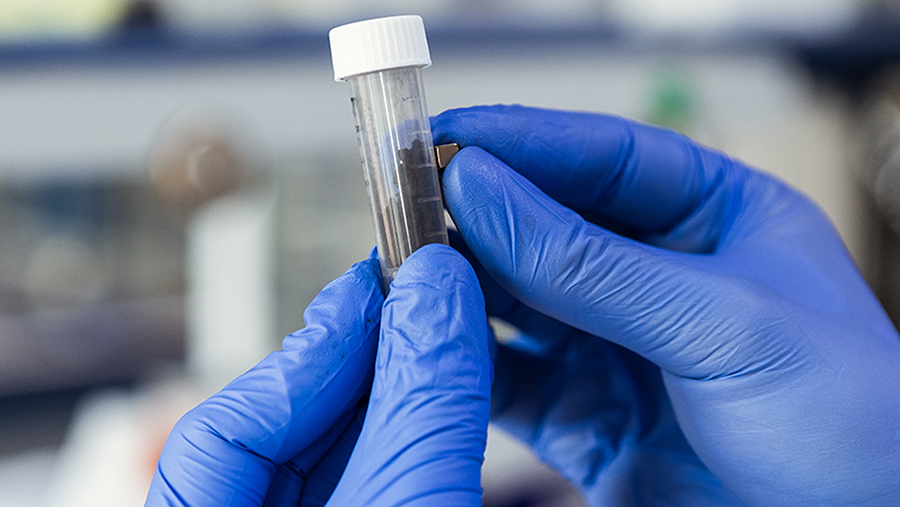

Scientists have designed a new type of reactor for faster and cheaper extraction of "green" hydrogen. They have developed a method that uses magnets and nanoparticles to speed up the decomposition of water into hydrogen and oxygen six times and reduce energy consumption by 15%. The semi-industrial prototype of the reactor assembled in the laboratory is ready for testing in real production, the developers said. For more information, see the Izvestia article.

What kind of hydrogen is called green

ITMO scientists have created a new type of reactor for water electrolysis, which makes it possible to speed up and reduce the cost of this process. They modified the reactor with magnets and applied special iron-cobalt nanoparticles to its electrodes. This led to a six-fold acceleration of electrolysis reactions. In addition, the amount of energy consumed has decreased by 15%: to produce 1 kg of hydrogen in such an electrolyzer, 48.8 kWh of electricity is required instead of 57.3 kWh of electricity.

The basic operating mechanism of the reactor remained the same as in the classical versions of the equipment. An alkali is poured into the liquid compartment, two electrodes are lowered there and an electric voltage is applied to them. In the solution, the electrical circuit closes, and under the action of an electric current, water molecules break up into hydrogen and oxygen molecules. The former are formed on an electrode with a negative charge — the cathode, and the latter with a positive charge — on the anode.

— Magnetic nanoparticles affect the electronic state of water intermediates so that they react faster and more efficiently. This reduces the amount of energy consumed to activate these processes. In conventional reactors, these mechanisms are also observed, but they proceed with significantly lower efficiency and solely due to electric current," Ilya Shabalkin, a graduate student at the chemical biology cluster and a junior researcher at the ITMO Advanced Engineering School, told Izvestia.

Hydrogen is used in the chemical, oil refining, glass and food industries, metallurgy, and even nuclear power plants. It is necessary for the production of ammonia, methanol, various metals and solid fat, which is part of margarine and soap. In addition, hydrogen is an efficient alternative energy source. On an industrial scale, hydrogen is usually produced by heating methane and water vapor to 700-1000°C. However, as a result of this chemical reaction, not only hydrogen is formed, but also carbon dioxide.

A more environmentally friendly way to extract hydrogen is by electrolysis of water. Under the action of an electric current, water is split into environmentally friendly hydrogen and oxygen, which is why such hydrogen is called green. But the main disadvantage of this method for industry is the high cost.

The scientists observed all the reactions during experiments on a semi-industrial prototype reactor assembled in the ITMO laboratory. Chemists synthesized nanoparticles themselves and printed polymer parts for the reactor vessel on a 3D printer, choosing the most efficient design. Their installation is ready for the scaling stage. The scientists are currently planning to find industrial partners and test the reactor in real production.

Achievements in the field of "green" energy

The magnets and catalysts used make it possible to speed up the process of producing hydrogen while reducing energy consumption during electrolysis, Andrei Gorbunov, director of the Autonomous Non-Profit Organization Vostochny Hydrogen Cluster Management Company, told Izvestia. Since water electrolysis is currently considered the most expensive due to the high energy consumption in the production of hydrogen, a 15% reduction is a high achievement.

Potentially, the development can be useful for practical implementation, however, technical and technological difficulties may arise with the integration of the magnetic system into industrial electrolysis modules, said Alexey Levchenko, head of the Competence Center of the NTI PHC PHF and MH RAS.

— This work is one of many aimed at improving the efficiency of water electrolysis, where magnets or electromagnets are integrated into a conventional electrolysis cell. There are quite a lot of works devoted to the study of the influence of the magnetic field on the efficiency of electrolysis," the expert noted.

Such reactors are promising for several reasons at once, explained Evgeny Alexandrov, Director of the NTI Center for Digital Materials Science: New Materials and Substances at the Bauman Moscow State Technical University.

— Firstly, they were printed on a 3D printer, which makes them available for a variety of designs and easily replaceable. Secondly, adding magnets is a cheap, simple and simply elegant solution. The electrocatalytic properties of iron-cobalt nanoparticles in the splitting of water are already known, but the effect of a magnetic field on their activity has been studied for the first time, the expert said.

Thirdly, the reactor design improves mass transfer, reduces the need for additional mixing devices, which increases its reliability, the specialist said.

The study is supported by the Priority 2030 program. The results are published in the Chemical Engineering Journal.

Переведено сервисом «Яндекс Переводчик»