Strong ratios: electrically conductive concrete will strengthen houses and roads in the Arctic

- Статьи

- Science and technology

- Strong ratios: electrically conductive concrete will strengthen houses and roads in the Arctic

Scientists have increased the strength of concrete by 48%, and also gave it the ability to conduct current by adding a small amount of graphene oxide to it. By measuring the electrical conductivity of the obtained material during operation, it will be convenient to monitor its condition, for example, the appearance of deformations. The new composite can also become the basis of energy-efficient coatings for heating roads and floors in buildings. In addition, the authors of the project have developed a model of crack formation in modified concrete, which will extend the life of structures built in the conditions of the North and the Arctic. For more information about the technology, see the Izvestia article.

Why do we need electrically conductive concrete?

Researchers from the V.P. Larionov Institute of Physico-Technical Problems of the North of the Siberian Branch of the Russian Academy of Sciences and the M.K. Ammosov Northeastern Federal University (Yakutsk) have improved the properties of concrete, one of the key building materials. The scientists added graphene oxide, obtained from industrial waste, to its composition and modeled the process of cracking in such a composite.

As experts told Izvestia, composite materials consisting of two or more components are increasingly used in construction. Their main advantage is that they combine the beneficial properties of the constituent substances. For example, fiberglass can be used instead of steel for reinforcing concrete structures: it is lightweight, durable and corrosion-resistant. However, it also has disadvantages — high cost, low fire resistance and fragility under excessive loads. Therefore, scientists are looking for new compositions of composites that not only surpass traditional materials in strength, but are also able to "report" their condition — for example, when there is a risk of deformation or destruction.

Graphene is a durable and conductive material, it consists of carbon layers one atom thick. Due to these qualities, it can increase the strength of building materials, as well as give it the ability to conduct current. The latter property can be used to track the state of the composite. For example, a decrease in conductivity may indicate excessive loads and the risk of structural failure.

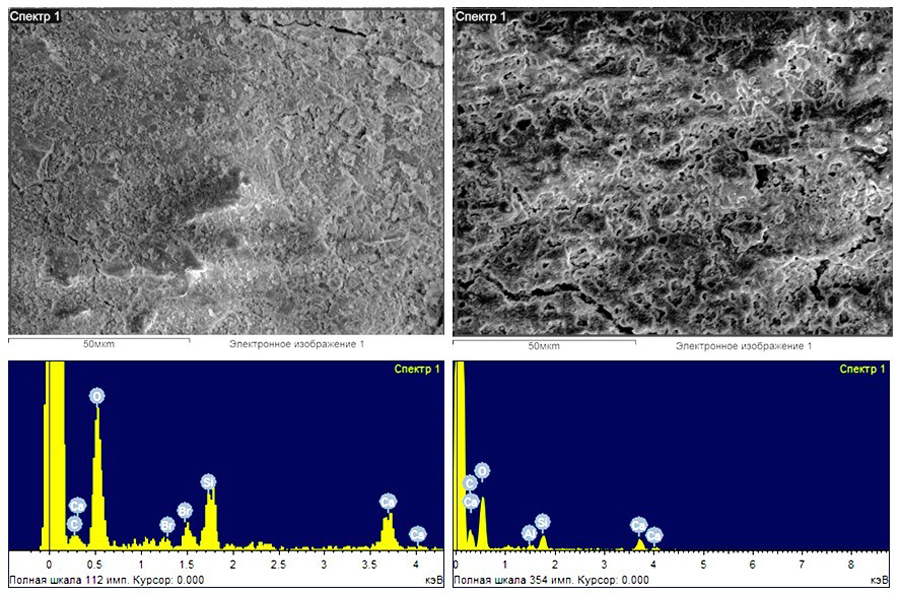

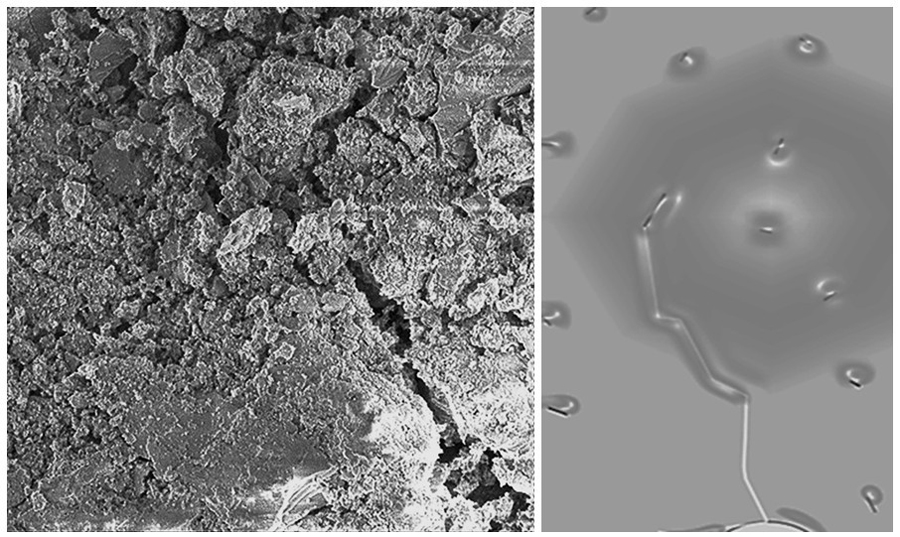

However, studies show that when added to cement mixtures, pure graphene forms dense clusters and is unevenly distributed in the material, which reduces its reinforcing effect, the scientists said. Therefore, to evenly distribute its particles in the cement matrix, the authors used graphene oxide. Due to oxygen-containing groups, it interacts better with the surrounding material than pure graphene, and therefore does not stick together into aggregates. The researchers produced concrete samples with the addition of 0.2 and 0.5% of this modifier.

The scientists then tested the mechanical and electrical properties of the initial sample and the modified concretes. To do this, the samples were compressed on a laboratory setup and their electrical resistance was monitored at the same time. It turned out that the addition of graphene increased the strength of concrete by 48%.

In addition, concrete, which normally does not conduct current, has acquired this property. Moreover, the electrical conductivity of the material changed in response to mechanical stress. When the sample was compressed, it slowly increased, but when loads close to the ultimate strength were reached, it dropped sharply. Due to this, data on the electrical conductivity of modified concrete can be used to identify excessive loads. In construction, this approach will allow monitoring the condition of buildings, bridge supports and other structures.

— Due to the ability to conduct current, such concretes can be used not only to monitor the strength of structures, but also for economical heating of road surfaces and indoor floors, protection against corrosion and frost cracking of reinforced concrete structures. In addition, they could potentially act as wireless charging on the roads for electric vehicles. In the future, we plan to simulate the effect of electric current on the process of destruction of such a material at low temperatures and the possibility of energy accumulation in it," said Valery Lep, project manager, full member of the Academy of Sciences of the Republic of Sakha (Yakutia), chief Researcher at IFTPS SB RAS.

Where the technology will be used

The authors also developed a numerical model that makes it possible to evaluate the resistance of modified concrete to cracking. It will be useful for assessing the reliability of composite structures, especially in extreme conditions, for example, at low temperatures in the Arctic regions of our country, the scientists said.

The research fundamentally changes the role of concrete in construction, it becomes a new generation composite that combines a bearing function, self-diagnosis and additional useful properties, Dmitry Suvorov, senior researcher at the Department of Functional Nanosystems and High-Temperature Materials at NUST MISIS, told Izvestia. The introduction of technology can significantly increase the safety, durability and energy efficiency of construction, primarily for responsible and specialized facilities, including in the Arctic, where the requirements for durability and safety are maximum.

"The main issues for scaling are likely to be the cost of graphene oxide, which in this case was solved by using recycled materials, as well as developing additive technologies to eliminate the agglomeration of nanoscale wafers," the expert said.

This is a fairly well-known technology. To date, it has become widespread in underfloor heating in the form of cable, there are also heating ceramics and heating concrete, where carbon black is used as an electrically conductive material, said Vyacheslav Seleznev, associate professor of the Department of Mechanical Engineering, Marine Engineering and Transport at FEFU, NTI TechNet expert.

— These coatings must have a limited operating temperature, which must be maintained. I believe that for widespread use, in addition to special coatings where it is necessary to maintain an accurate temperature, it is enough to simply embed heating cables in monolithic concrete or use other heating technologies through fittings," the specialist said.

The results of the study, supported by a grant from the Russian Science Foundation (RSF), are published in the journal Natural Resources of the Arctic and Subarctic.

Переведено сервисом «Яндекс Переводчик»